Metal Household Products Sheet Metal Stamping Part

Basic Info

Model No.: 855645

Product Description

Stamping:

1.stamping ,machining, die casting, turning

2.OEM,can be customized

3.Alloy,SS, Aluminum,Brass,steel

4.durable

Specifications:

Design: We use the most advanced mould design software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T)

Manufacture: We use With advanced technology, unmatched skill, professional and advanced equipment size range from 15T-160T, and experienced technicians to fit our customers requirements, like tooling manufacturing, stamping and surface treatment service

Product Material: Stainless steel, carbon steel, aluminum, brass, and so on

Making process: Progression die, Stamping, deep drawing, Bending, Punching, Threading, Welding, Tapping, Riveting, Grinding, CNC machining

Surface treatment: Anodizing, Powder-Coating, Zinc-Plated, Chrome coated ,Nickel Plated ,Hex Chromates Zinc, Rust-inhibiting oils, Electrophoresis, Paints and primers, blacking, etc

Lead time: 20-50days based on the different products

Packaging: canton case or as per customers' requirement

Certification: ISO9001:2008

Industry: these parts are used in Automotive, Electrical, Building, Furniture, Machine assembly, Computer, Air industry. OEM/ODM Electronics

OEM orders are welcomed, for any stamping part

Specifications

grinding China machining parts

1. OEM manufacturer

2. Non-standard parts

3. Welcome to make prototypes

Materials : Iron, aluminum, steel, copper, plastic, carbon steel, nylon, bronze, solder alloy, HSS, tool steels, or as per the customers' requirements.

Dimensions : According to customer's drawing

Surface treatment : Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting and so on.

Packing : Wooden box, or as per the customer's requirements

Processing equipments : CNC machining center, CNC lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc.

Service project : To provide production design, production and technical service, mould development and processing, etc.

Testing machine : Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on.

Minimum order quantity : negotiable

Delivery : 7-15 days after T/T 30% deposit

Business scope : CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc

Application : Automation machine, medical device, industrial machine, automobile, electric appliance, and other industries.

Min order and sample order is acceptable.

Machining service as per your requests and specification drawings, either small or large quantity is acceptable for us.

We are sincerely expecting to cooperate with you.

Contact us if you need more details on Radiator Frame Assembly. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sheet Metal Part、Pure Iron Metal Product. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.stamping ,machining, die casting, turning

2.OEM,can be customized

3.Alloy,SS, Aluminum,Brass,steel

4.durable

Specifications:

Design: We use the most advanced mould design software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T)

Manufacture: We use With advanced technology, unmatched skill, professional and advanced equipment size range from 15T-160T, and experienced technicians to fit our customers requirements, like tooling manufacturing, stamping and surface treatment service

Product Material: Stainless steel, carbon steel, aluminum, brass, and so on

Making process: Progression die, Stamping, deep drawing, Bending, Punching, Threading, Welding, Tapping, Riveting, Grinding, CNC machining

Surface treatment: Anodizing, Powder-Coating, Zinc-Plated, Chrome coated ,Nickel Plated ,Hex Chromates Zinc, Rust-inhibiting oils, Electrophoresis, Paints and primers, blacking, etc

Lead time: 20-50days based on the different products

Packaging: canton case or as per customers' requirement

Certification: ISO9001:2008

Industry: these parts are used in Automotive, Electrical, Building, Furniture, Machine assembly, Computer, Air industry. OEM/ODM Electronics

OEM orders are welcomed, for any stamping part

Specifications

grinding China machining parts

1. OEM manufacturer

2. Non-standard parts

3. Welcome to make prototypes

Materials : Iron, aluminum, steel, copper, plastic, carbon steel, nylon, bronze, solder alloy, HSS, tool steels, or as per the customers' requirements.

Dimensions : According to customer's drawing

Surface treatment : Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting and so on.

Packing : Wooden box, or as per the customer's requirements

Processing equipments : CNC machining center, CNC lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc.

Service project : To provide production design, production and technical service, mould development and processing, etc.

Testing machine : Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on.

Minimum order quantity : negotiable

Delivery : 7-15 days after T/T 30% deposit

Business scope : CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc

Application : Automation machine, medical device, industrial machine, automobile, electric appliance, and other industries.

Min order and sample order is acceptable.

Machining service as per your requests and specification drawings, either small or large quantity is acceptable for us.

We are sincerely expecting to cooperate with you.

Product Categories : Stamping Parts > Metal Stamping

Hot Products

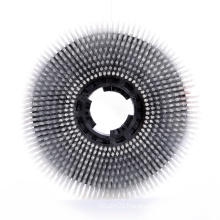

Plastic Bottle Cleaning Brush with Handle (YY-476)Foam RollerCopper Nut for Bruckner Stenter Machine (YY-414)Nylon or Bristle Material Textile Round Brush (YY-252)Hair Brush (HB-088)Duster (CB-D-007)Paint Brush (EB-004)Drop Cloth (PT-DC-001)Goat Hair Mixed with White Bristle Paint Brush (YMB-002)Artist Brush (921)Iwire Brush (B-WB-026)Pental Eterna Scraper with Plastic Handle and Iron Edge (PK-0012)2.5inch Steel Wire Knotted Cup Brush (YY-039)PP Material Strip Road Sweeper Brush (YY-033)Nylon Material White Colour Strip Round Brush (YY-009)PP and Steel Wire Mixture Side Street Brush (YY-001)